Print with Confidence. Capital.

with four decades of experience and a deep commitment to sustainability, Capital Printing ensures your projects exceed expectations and stand out—with confidence.

We’re ready to transform your next project.

From design to fulfillment, we’re ready to execute your project with confidence and seamless efficiency. Partnering with Capital means exceptional print and packaging solutions that truly elevate your brand.

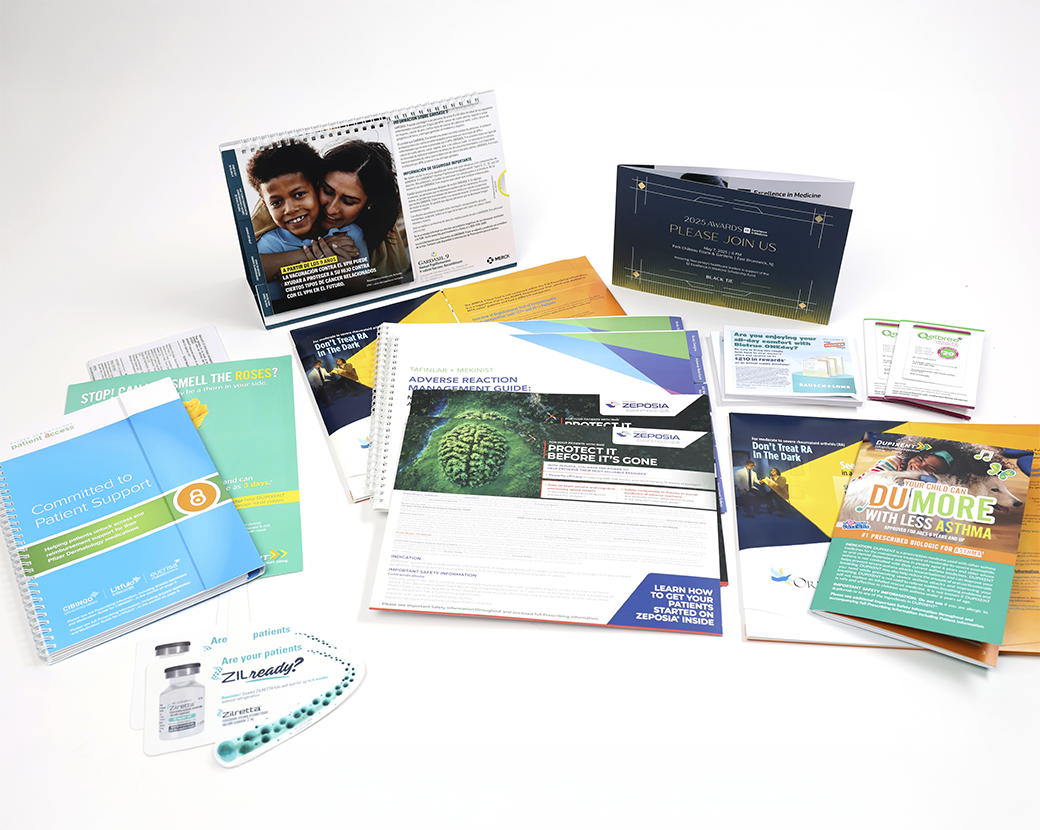

Marketing Collateral

From brochures and sales kits to posters and more, we create impactful materials that deliver your message clearly and ensure your brand stands out with confidence.

- Brochures, flyers & catalogs

- Direct mail campaigns

- Sales aids and detail aids

- Leave behind materials

Dimensional Pieces

Whether you need custom promotional kits or specialty packaging, we handle every aspect in-house with expert finishing and streamlined processes.

- Capacity pocket folders

- Easel backs and brochure holders

- Welcome kits

- Table tents and display stands

Packaging

Elevate your product with packaging that balances functionality and visual appeal. From simple cartons to intricate designs, we deliver efficient, cost-effective solutions—ensuring durability, accuracy, and premium finishes with the latest UV curing technology, precision die-cutting, and inline folding-gluing.

- Folding cartons

- Luxury packaging

- Display boxes and retail shelf packaging

- Direct Mail packaging

Packaging Inserts

Our dedicated PI production department guarantees compliance through advanced automation, prioritizing accuracy and efficiency.

- Client portal with real-time order tracking, job status, and production data

- Efficient, high-speed printing on lightweight stocks

- Folding equipment for complex patterns, including mini-folding and inline gluing

- Quality assurance and regulatory compliance to ensure accuracy and consistency

Our Capabilities bring expertise to every step.

With extensive in-house manufacturing and state-of-the-art equipment, we bring projects to life with precision, quality, and efficiency. Every stage of production is carefully managed to ensure seamless execution, delivering results you can trust.

Before we go to press

- Packaging structural design & dieline development

- CAD-cut prototypes for accuracy & feasibility testing

- In-house die storage for streamlined reprints & workflow efficiency

- Seamless file compatibility across all graphics applications

- Digital & hard-copy contract color proofing

- Expert retouching & color correction

- Advanced RIP & trapping workstations for optimized print quality

- Secure data backup & recovery system

- Short-run production

- High-resolution, on-demand printing

- Personalized and targeted printing

- Seamless integration with offset and hybrid workflows

- Versatile substrate compatibility

- Web-to-print solutions

- State-of-the-art Heidelberg presses with advanced automation

- Up to 6-color printing with aqueous & UV coating

- High-resolution screening for superior print detail & clarity

- Closed-loop color management for consistent, accurate color reproduction

- Interdeck UV drying system for instant curing & faster turnaround

- Custom coating textures & effects for enhanced finishes

- Supports 27# opaque to 48pt paper board for versatile applications

- Coldset 2-unit press for efficient, high-volume printing

- 38” maximum web width with 22 ¾” cutoff

- Optimized for lightweight stocks & cost-effective production

- Dual roll stands for continuous high-capacity runs

- High-speed VITS sheeter for increased efficiency

Finishing

- Die-cutting with automated blanking and stripping

- Foil stamping & embossing

- Saddle-stitching lines with up to 8 pockets & optical readers

- High-speed inline gluing, folding & inserting

- Packaging inserts

- Customized for high-speed folding on lightweight stock

- Mini-folding

- Perfect binding

- Spiral & Wire-o binding

- Padding

- Shrink-wrapping & poly-bagging

- Card affixing and tip-on gluing

Kitting & Fulfillment

- Hand assembly for custom & specialty packaging

- Drop shipments for direct-to-destination delivery

- Hand assembly for custom & specialty packaging

- Warehousing & inventory management for seamless supply chain control

- Web-based ordering, tracking & reporting for real-time visibility

Data-driven insights make for confident decisions.

Capital Business Intelligence is an advanced analytics platform that turns real-time manufacturing data into actionable insights, giving you the transparency and control needed to manage print activity, reduce costs, and improve vendor relationships.

Monitor Print Spend and Benchmark Pricing

Analyze department and category spend, compare periods, and benchmark pricing to drive transparency and savings.

Track Cost Savings and Sustainability Impact

Measure financial and environmental impact over time to support smarter, more responsible decisions.

Manage Direct-to-Buy Paper Programs

Oversee purchasing and vendor activity with clear reporting to improve transparency and maximize value.

Real-Time Reporting

Access real-time reporting from direct-source data for greater accuracy, with export options for easy sharing and analysis.

At Capital, we’re confidently bringing visions to life.

“Integrity, authenticity, and keeping your word are the keys to lasting success.”

– Nolan Russo, Sr.

About Us

Capital Printing is a certified Woman-Owned Business (WBENC) with over four decades of innovative print experience. Proudly operated across two generations, we honor the legacy of our founder, Nolan Russo Sr., by upholding his belief that success comes to those who build authentic relationships and remain committed to customer satisfaction. At Capital, we aim to instill confidence in every partner through our comprehensive capabilities and unwavering commitment to excellence.

See what our clients are saying:

“Capital Printing is one of those “go to” companies. Always willing to go the extra mile—customer service, pricing and quality are always on target. They understand our business, provide great solutions and are all around nice people to work with. Capital Printing is a true partner.”

“I have been working with Brett and her team for over 10 years now. I feel that they are an extension of my business. They think of the things I might forget and always come with new ideas or a better way to produce a job. Best of all, they truly care about what they do.”

“Ever since I began working with Capital, I’ve been treated as a friend and colleague, instead of a simple print partner. Not only has Capital consistently provided the best pricing, timing, and quality of work around, they are always a joy to work with.”